Manufacturing FFKM, FKM AED LT, FEPM, HNBR AED LT, Precision Machinery Metal Plastics and Rubber

- +971 50 555 6196

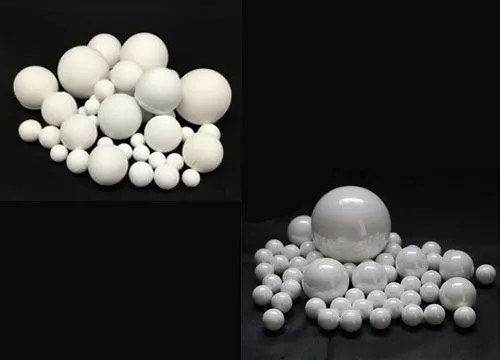

Ceramic Balls

Ceramic Balls

Ceramic balls are particularly suited to harsh environments. Their main advantages over steel is that they have a density of 40% tower than steel. Have 29% lower thermal expansion and are 150% harder.

Ceramic Balls:

Ceramic balls are particularly suited to harsh environments. Their main advantages over steel is that they have a density of 40% tower than steel. Have 29% lower thermal expansion and are 150% harder. In certain high-speed applications their life is extended by as much as a hundred times. The three main materials used are Alumina Oxide, Zircona Oxide and Silicon Nitride.

SL3N4 Silicon Nitride:

The most widely used type of ceramic due to very high resistance to wear and abrasion in general. It has a micro – structure specially designed for applications subject to great stress. It does not require lubrication, it is resistant to corrosion, anti magnetic and electrically insulating, and it continues to be efficient at high temperatures up to +1400 °C. It combines extreme hardness with a high precision ball. Si3N4 balls are widely used in high precision bearings in the airspace industry, for machine tools, measurement instruments, mechanical centrifuges, radar and missiles, pumps and compressors.

Al203 99.50% ALUMINA (ALUMINA OXIDE):

The material has a multi-crystal structure and excellent resistance to abrasion and high temperatures. It is resistant to most corrosive agents, but it is not recommended for use in contact with hydrochloric and hydrofluoric acid or strong alcaline solutions. Al203 balls are used in valves, pumps and ball bearings.

Zr02 ZIRCONIUM OXIDE:

The material, compared has a high degree of compactness and considerable flexural strength, which makes it very reliable. It also has a low modulus of elasticity, close to that of steel, together with an extraordinarily low thermal conductivity.

AL203 99.99% RUBY:

This material has a non porous single crystal structure used where particular hardness and extreme resistance to wear are required together with a low specific weight and properties of chemical inertia. The material consists of pure aluminium oxide with a small percentage of chromo oxide which gives it its characteristic red colour, which is the most visible feature of these balls in many applications as measurement and control instruments, valves and pumps.

AL203 99.99% SAPPHIRE:

This material has a single crystal structure and unlike ruby is transparent. Because of its optical properties and high refraction index. Balls made of this material are currently used as chemically inert lenses.

CERAMIC BALLS – PROPERTIES OF MATERIALS

| PHYSICAL PROPERTIES | SAPPHIRE AND RUBY | ALUMINA OXIDE | SILICON NITRIDE | ZIRCONIUM OXIDE |

| STRUCTURE | single crystal | multi-crystal | multi-crystal | multi-crystal |

| CHEMICAL FORMULA | AlA | AlA | Si3N4 | ZrO, |

| PURITY % | 99.99 | 99.8 | 95.00 | 97.00 |

| DENSITY g/cm, | 3.99 | 3.90 | 3.20 | 5.50 |

| OPERATING TEMPERATURE °C | 1800 | 1100 | 1000 | |

| MELTING POINT | 2050 °C | 2050 °C | 1900 °N | |

| SOFTENING POINT | 1800 °C | 1725 °N | 1400 °N | |

| SPECIFIC HEAT AT 25 °C (CAL/g/°C) THERMAL CONDUCTIVITY | 0.18 36 W/m°k | 0.25 29 W/m°k | 0.17 29 W/m°k | 9 W/m°k |

Ceramic Balls Manufacture And suppliers in Dubai, UAE

Applications

- Automotive

- Fluid Power

- Electronics

- Hydraulic Fittings

- Valves and Pumps

- Earthmoving & Construction Equipment

- Power Generation

- Instrumentation

- Filtration

- Hydraulic Cylinders

- Plumbing Products

- Petrochemicals

- Chemicals & Fertilizer Plants

- Pharmaceuticals

- Pneumatic Cylinders

- Dairy/Food Processing

Menu